More than 16,000 pipes, 420 induction bends and 16 electrical room modules were unloaded and mobilized through its docks, a process that required over 4,200 work shifts.

Iquique Terminal Internacional (ITI) described the handling of more than sixteen thousand five hundred pipes arriving from Greece—destined for Collahuasi’s C20+ Project—as one of the most important and challenging cargo operations in recent years. The operation required a complex logistics plan both inside and outside the port to efficiently support this major regional investment.

According to ITI’s Operations Manager, Cristopher López, “This process involved the movement of more than 94,000 tons of cargo from five vessels. It challenged us logistically, not only in vessel servicing operations, but also in the distribution of cargo within the terminal, in our storage areas, and in establishing an additional storage and distribution zone in Alto Hospicio. Once unloaded at the port, we transported the pipes using trucks, performing more than 5,500 trips from Iquique to Alto Hospicio.”

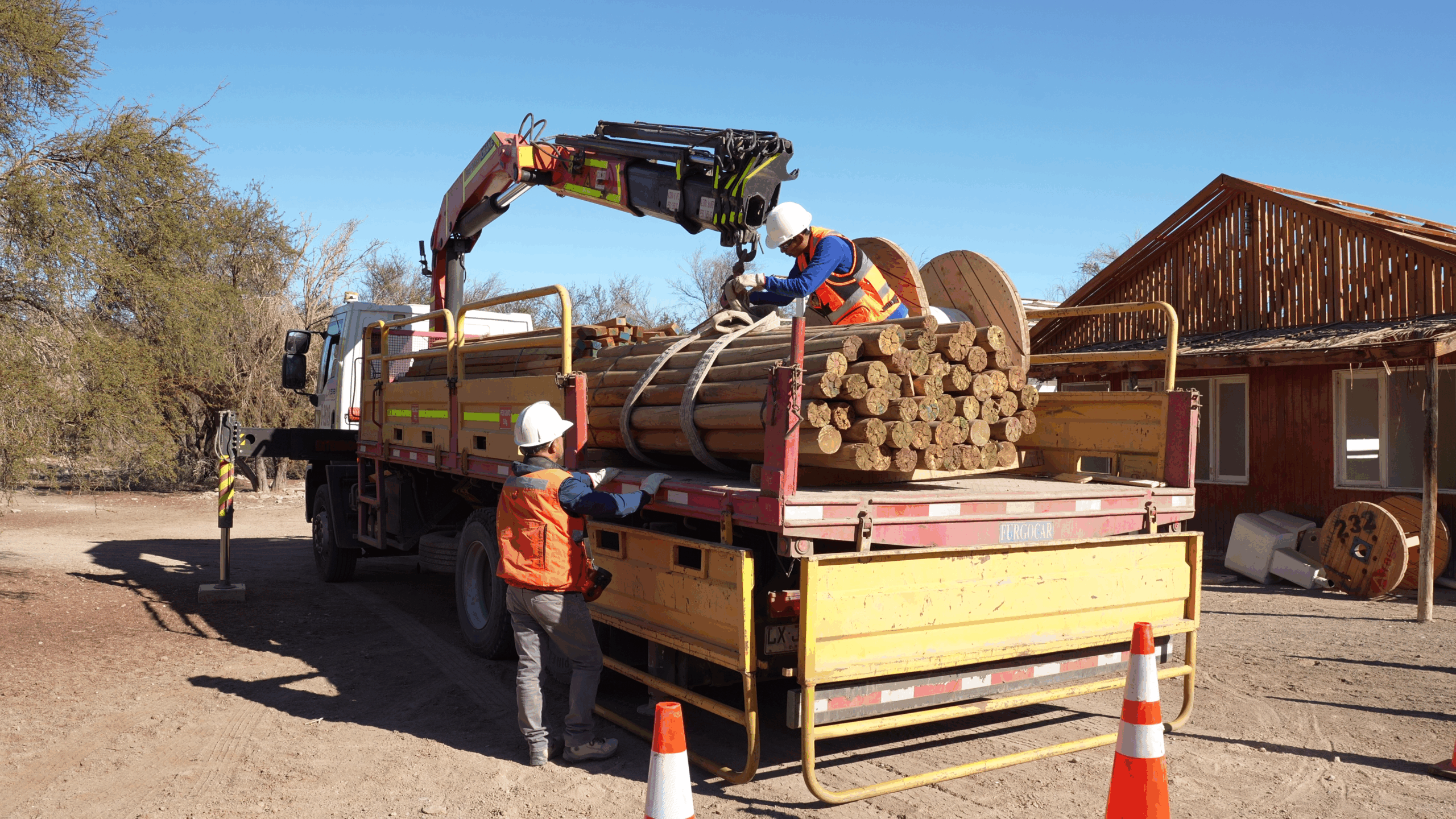

In this regard, Carlos Machuca, Contracts and Procurement Manager for the C20+ Project, stated that “The ITI team successfully integrated local carriers, as requested, to transport the 16,000 pipes from the port to a dry port. Once the vessels arrived, local trucking companies transported the cargo from the terminal to that distribution point. We also worked with regional companies to move the pipes from the port to the Andes, and this was achieved without any accidents, which is the most important part.”

Both ITI and the local transport companies responsible for moving the pipes and electrical rooms emphasized the collaborative work, employment generation and participation of Tarapacá-based companies in the mining project, which involves constructing a desalination plant at the company’s port and has already invested more than US$230 million in the region. “This effort generated more than 4,200 work shifts, incorporated several contracting companies in transportation and logistics, and reinforces that mining projects—particularly those linked to port operations—generate significant social impact in terms of workforce development,” said López.

For Eduardo Valenzuela, General Manager of Transportes Valenzuela Silva Ltda., partnership and collaboration were key to success. “We brought together different trade associations from Iquique and Alto Hospicio to distribute the work, as requested by Collahuasi. On average, we operated with around 60 trucks, and approximately 150 people, including direct and indirect workers.”

Valenzuela noted that C20+ represented both a challenge and an opportunity for the region’s freight transport companies. “It was a valuable learning experience—helped us grow, gain visibility, and position ourselves for future work, both with Collahuasi and with other contractors. It was a very important step.”

Machuca also explained that “The electrical rooms were transported from the Port of San Antonio to Iquique, requiring specialized logistics due to their size, configuration, and weight. These were oversized and heavy cargo units, posing significant challenges that were successfully addressed with the support of local port companies. Both ITI and EPI (Empresa Portuaria Iquique) were key to solving this.”

At the Iquique Port Company (EPI), key logistical operations also took place for Collahuasi: the arrival of the vessel Yagana enabled the assembly of intake and discharge pipelines for the desalination plant; the barge Naval II transported and delivered rock materials used to protect underwater infrastructure; and the vessel Oxxean Mars has transported various supplies for marine works, along with support vessels assisting divers near the project area.

“Today, both ITI and EPI are fully prepared to receive and support projects of this scale—this is the level of infrastructure that large-scale mining now demands,” concluded Machuca.